Date: Thursday, 25th July, 2019

Time: 12:30pm – 6:00pm

Site Location: Siemens House, Varey Rd, Congleton, CW12 1PH.

The IEEE Power and Energy Society Student Branch Chapter University of Manchester organised a site visit to Siemens Digital Factory in Congleton, UK. The event attracted 28 attendees across PhD and MSc students in School of Electrical and Electronic Engineering. The visit was FREE with transportation included.

Siemens’ Digital Factory designs and manufactures variable speed drives for motors. Its customers come mainly from the automotive sector, machine building (OEMs), pumps and fans and the airport industry. The plant is at the cutting edge of Siemens’ unique ‘North Star’ vision and uses virtual technology, including a futuristic 3D cave, to stand out as one of the true pioneers of factory design today.

The visit was split into three parts. The first part began with Mr Ian Baron, the Electrical Team Manager, giving a brief introduction of the Congleton site. Then, three representatives for the Gradate Development Programme and Internship Programme of Siemens shared their own experiences working in the company, highlighting their great experiences of working with real products and solving practical problems for the customers.

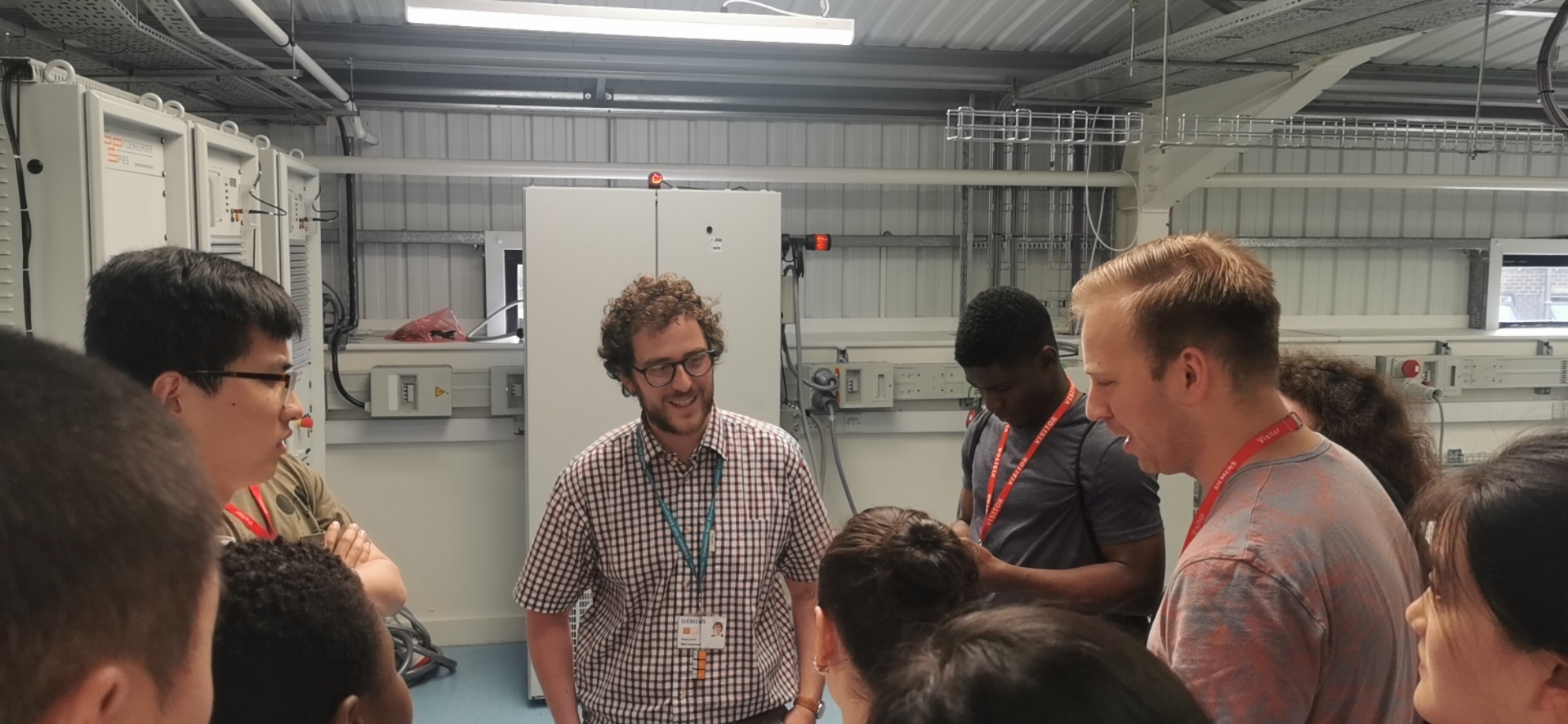

The presentations were followed by an interactive “Show & Tell” session where three sample motor drive products and a number of tool kits were provided to the visitors. The Siemens representatives helped the visitors dissembled the motor drives and introduced the functionalities of each part. Many questions were asked and answered with knowledge being exchanged.

During the third part, the visitors were divided into two groups taking turns to visit the Research & Development Facility and the motor drive factory. In the “G Building” where the R&D takes place, staff of Siemens showed and explained different sections of test facilities to the visitors. During the tour to the factory, the visitors were showed with the entire manufacture line of a motor drive, from soldering electronic components to a printed circuit board, to function testing of the board and the final products. Siemens kindly provided all the personal protective equipment required to enter the manufacturing area.

This event was well received with highly positive feedbacks from the participants. The IEEE PES SBC at the University would like to thank every participant for joining the visit and many thanks again to Siemens, Congleton for the visit and all the useful information provided!